Calor proves a recipe for success at Iceland Manufacturing

When Iceland Manufacturing Limited decided to switch from oil to LPG from Calor to fuel its commercial ovens in a more reliable and environmentally friendly way, it was vital the changeover could be made quickly, without causing disruption to the manufacturing process.

Although it’s based in a built up area in Gorton, Manchester, relatively close to the city centre, the company doesn’t have access to mains gas across its entire site, meaning an alternative fuel is required for its three commercial ovens.

Tony Bennett, Department Manager (Engineering) at Iceland Manufacturing said:

“We aim to minimise our operations’ impact on the environment as much as possible, but our commercial ovens were previously running on oil, which isn’t a particularly clean burning fuel. The oil burners were also proving both unreliable and expensive to operate, and we encountered some leakage issues, so we investigated the alternatives.

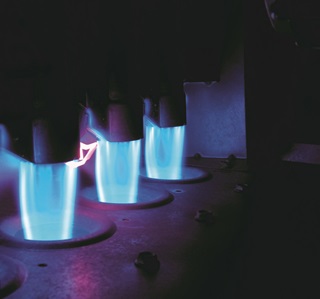

Following an initial site visit, Calor Gas was chosen to replace the external pipework on site and install three new LPG burners in the commercial ovens.

LPG has the lowest carbon emissions out of all the fossil fuels available to those without access to mains gas, so it helps us to operate more sustainably.”

In order to minimise disruption during the switch from oil to LPG, Iceland Manufacturing remained in close contact with Calor, as Tony explains:

“Our operation requires constant heat, so any prolonged periods of downtime due to the fuel supply can be very costly for the business. It was, therefore, vital that the LPG installation could be completed in as short a timeframe as possible.

An installation date was agreed with Calor, and its team then set about replacing the external pipework and installing six, 2,000 litre above ground tanks in preparation for the new burners going in – while we remained in full operation.

The new burners were then installed, tested and commissioned in half a day over the weekend, meaning we could resume full production the following Monday.

We opted for Calor because of its nationwide depot network and engineering expertise, and it’s proved to be a good decision. We’ve had no issues with the service received so far and are currently monitoring our usage trends before adding Calor's telemetry system to our tanks, which will mean the replacement of LPG becomes even more seamless.”